Key Updates

Key UpdatesJan. 2024CTE measurement of dielectric amorphous films

Dec. 2023ICP-OES to quantify unknown component elements

Nov. 2023Polymer characterization with multiple techniques: FTIR, GPC, Raman, TGA, and DSC

Oct. 2023Ion Chromatography analysis of solvent samples for fluorine in ppb level

Sep. 2023MALDI-ToF analysis of polymer samples

Aug. 2023ICP-MS and IC anion analysis for new electrolyte development

Jul. 2023Unknown particle defect analysis on wafer using TEM-EDS

Jun. 2023Purity analysis of organic material batch using ICP-MS and IC

May 2023Cs-TEM-EDS of a bulk copper piece coated with unknown graphene.

Apr. 2023SEM-EDS on a glass piece to identify defects.

Mar. 2023X-sectional polishing of LED device for FA at interfaces

Feb. 2023Nano-scale analysis of onion shape graphene with Cs-TEM

Jan. 2023EBSD analysis of tungsten film

Dec. 2022Structure/composition analysis of HEMT by TEM/EDS

Nov. 2022Two-side Polishing of Micro LED Device

Oct. 2022Unknown coating material analysis of parts used in plasma process chamber

Sep. 2022Layer structure analysis of graphene using Cs-TEM

Aug. 2022Failure analysis of metallized ceramic using 3D CT, CSAM, and SEM-EDX

Jul. 2022Karl Fisher/FTIR/GC-FID analysis of an organic solvent

Jun. 2022C-, F-, and H- NMR analysis of organic solutions for graphene

May 2022XPS analysis for an identification of organic contaminations

Apr. 2022TEM/EDS analysis on HEMT device

Mar. 2022Hi-resolution d-XPS analysis for ITO for uLED application

Feb. 2022C-SAM for advanced wafer bonding technology

Jan. 2022Device structure analysis using FIB-TEM-EDS analysis of a whole wafer

Dec. 2021Electrical and structural analysis of high capacitance materials in MIM structure

Nov. 2021Cross-sectional failure analysis of micro-LED display parts

Oct. 2021 Analysis of biological molecules using Nanoscale FTIR

Sep. 2021 Quantification and identification of fungicidal toxins in fruit

Aug. 2021 Electrochromic device dopant identification and profile using ion milling and SSRM

Jul. 2021 Contaminant analysis of electrolyte solutions using ICP-MS and GC-MS

May 2021 Polymeric structural characterization using Nuclear Magnetic Resonance (NMR)

Apr. 2021 SEM analysis of battery composites

Mar. 2021 Fluorescence measurement of plastic films for research

Feb. 2021 DSC measurement of metal alloys for development

Feb. 2021 Metal composition testing by ICP for alloy development

Jan. 2021 Flash point measurements for solvents for development

Jan. 2021 Ion chromatography of semiconductor samples for failure anlaysis

Dec. 2020 Optical measurements on silver coated mirrors for research

Dec. 2020 LA-ICP-MS for trace metal analysis of semiconductor films for development

Nov. 2020 TGA measurements of polymer samples for development

Nov. 2020 TEM and EDS of LED Device Structures for failure analysis

Oct. 2020 XRR for density and thickness of dielectric films for semicondcutor development

Oct. 2020 XPS Depth profiles of metal oxide films for semiconductor research

Sep. 2020 NMR of polymer samples to measure ligand ratios for polymer development

Sep. 2020 Kelvin probe measurements of LED device structure for research

Aug. 2020 Heated ellipsometry measurements for medical devices for research

Aug. 2020 RBS measurements of ferroelectric thin films for memory development

Jul. 2020 Cross section SEM measurements on coated metals for semiconductor development

Jul. 2020 ToF depth profiles on LED device structures for semiconductor failure analysis

Jun. 2020 Extensive analysis of carbon powerder using TEM/EDS/TGA/XPS/FTIR/SEM for new graphene development

Jun. 2020 TEM+EDS analysis of GaN device structures for power device development

May 2020 Optical profilometry for defect characterization on transparent plastics for nuclear industry

May 2020 Reverse engineering of glue sample using DSC and FTIR for pest control failure anlaysis

Apr. 2020 GC-MS testing for toxicoloy of avocados for food development

Apr. 2020 Nano-FTIR of dielectric films for studying surface bonding for new semiconductor materials

Mar. 2020 M-SIMS depth profiles of doped material for optical telecommunication application

Mar. 2020 EELS Measurements on Dielectric films for semiconductor research

Feb. 2020 TEM/SEM/XRD/Uv-Vis analysis of Ag nanowires for transparent displays application

Feb. 2020 Measuring surface area of carbon powders using nitrogen gas for graphene industry

Jan. 2020 Polymer identification using TGA hyphenated to a GC-MS for semiconductor failure analysis

Jan. 2020 High Resolution ToF-SIMS depth profiles of Magnetic RAM (MRAM) development

Jan. 2024TSV analysis of DDR4 memory device

Dec. 2023Failure analysis of slighted opened coil

Nov. 2023CIS image sensor (Samsung and Sony) design analysis for IP litigation

Sep. 2023Structure analysis of HBM2 memory device packaging

Aug. 2023Die imaging of IC device for AI application

Jul. 2023x-sectional analysis of DDR5 focused on airgap and liner layers

Jun. 2023Multi-stack CIS image sensors from major brand smartphones

May 2023TSV structure analysis of DDR5 DRAM device

Mar. 2023Full process analysis report release of a SoC device of a major brand smartphone

Nov. 2022Top down high-resolution imaging of fin and gate from 14nm FinFET based device

Sep. 2022Package and process analysis of SoC used in major brand smartphone

Jul. 20223D CT failure analysis of new circuit board stack structure

Jun. 2022Decapsulation of metal packaged server CPU

May 2022Contract on the development of a new application of SCM for nano-LED application

Apr. 2022Die marking imaging for a full SSD products of a major manufacturer

Feb. 2022Image sensor dopant profile analysis in a smartphone camera of a key manufacturer

Jan. 2022Charge trap cell structure analysis of NOR and NAND devices from a major manufacturer

Dec. 2021Identification of top oxide layer on active fin from an advanced DRAM product

Nov. 2021Extensive reliability testing of a wearable device for health monitoring

Sep. 2021Comprehensive 5nm FinFET process analysis from Apple A14 AP chip from the 1st biggest foundry and functional block analysis is also done

Aug. 2021SCM & SSRM scanning, Hall measurement to check Ohmic contact to p-GaN in a nanowire LED device

Jun. 2021Comprehensive process analysis report for mobile SoC chip having 14nm FinFET process from the 2nd biggest foundry

Apr. 2021 OLED pixel analysis with dopant identification and profiles using Cs-TEM, u-spot d-XPS, and SCM

Mar. 2021 Complete functional block analysis of SSD SoC chips including SRAM size estimation for key

Feb. 2021 Thorough analysis of nanorod structure for u-LED application using Cs-TEM/EDS/EELS

Dec. 2020 High speed SSD (1700MB/s) SoC analysis with its SRAM and metal process

Jun. 2020 Merged contact structure comparison of Sony PS4 Pro, Xbox One X, and Nintendo Switch

Apr. 2020 3D NAND memory structure analysis with planeview and cross-section with Cs-TEM/EDS

Feb. 2020 Layer structure and material analysis of Micron DRAM with 20 nm technology

Sep. 2019 Toshiba image sensor analysis

Dec. 2019 Functional block analysis of Intel SSD SoC for 8TB product

Oct. 2019 Dopant profile and type analysis of Toshiba’s 15 nm technology-based NAND memory by SCM and SSRM

Sep. 2019 Charge trap memory cell analysis of 3D NAND Flash memory

Aug. 2019 65 nm node image sensor analysis used for SONY A9 digital camera

.png) |

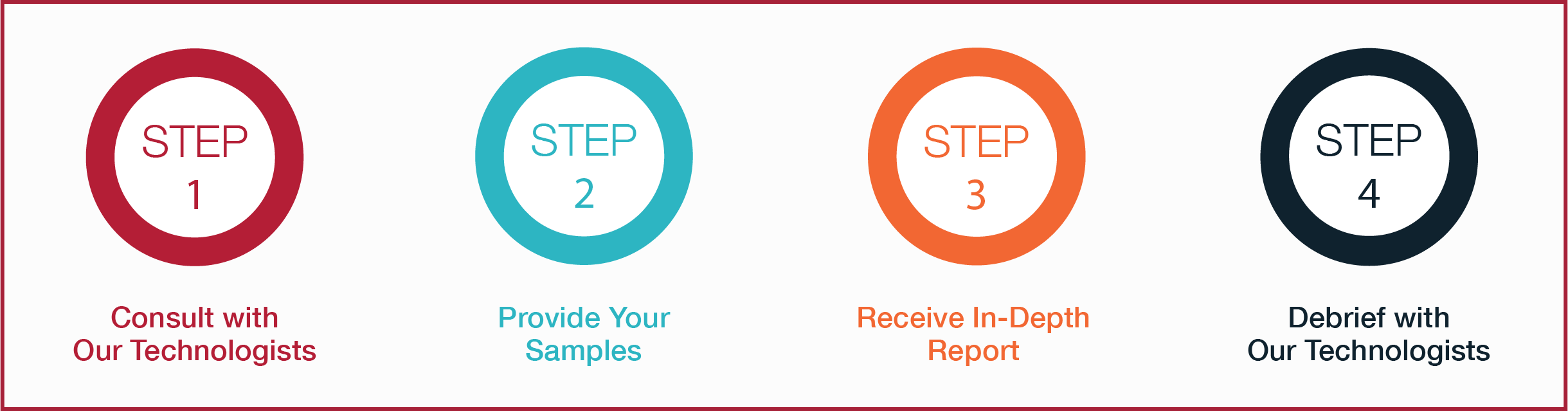

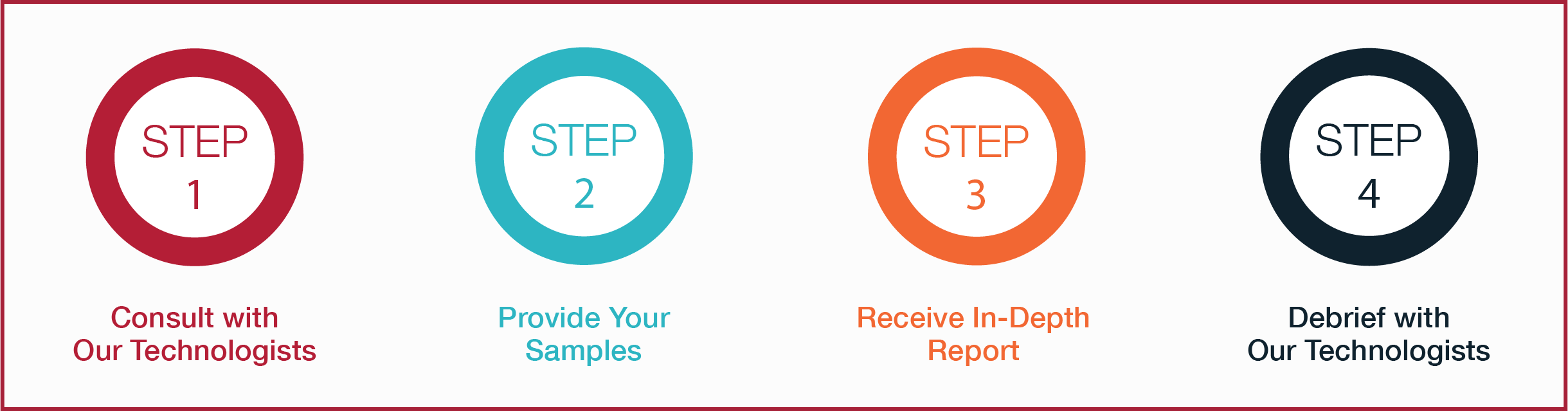

Streamline R&D Services Technology selection, management, payment with one single account |

.png) |

Affordable Price Access leading edge technologies at an affordable price |

.png) |

Solution Provider Utilizing scientific expertise both in-house and in-network to solve your challenges |

.png) |

Complimentary Consultation Before placing job order |

.png) |

Fast Turnaround Time Samples can be pre-diced or diced onsite furthur saving your time |

.png) |

Professional Data Interpretation As a second opinion to yours |

.png) |

Quality Assurance Program Free remeasurement if not satisfied |

The typical solution provider requires that customers be specific about the characterization techniques to be used to analyse their samples. This model of operation is lacking because more than often customers do not know enough about characterization. They can be specifying the wrong techniques and/or missing out on advanced techniques/tools that may provide better answers. Outermost understands as a high level what customers want to know and devises characterization plans to provide answers. They have access to the world's best and most advanced specialists, techniques, and tools and have provided me with answers, sometimes with methods that I did not know existed or were possible. I recommend Outermost to any engineer or scientist who wants answers.

Outermost has been very helpful, providing us with high-quality, valuable reverse engineering data and analysis in an expedient manner. Highly recommend.

I highly recommend Outermost Technology. I have been working with Outermost Technology for the past two years. The team is very professional and they come on-site to present and discuss the results after tasks where completed, which is very appreciated as it is unique in the industry. I highly recommend Outermost Technology.